New Products

Find Fiber Cement Skin Panels, Cementitious Structural Insulated Panels, Fiber Cement Sandwish Panels on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Min. Order: | 1 Others |

|---|

Model No.: CSIP001

Fiber Cement Board Sips Specification:

Facing: 0.9mm fiber cement board (for both side);

Core: 1.2 lb/c.f (20kg/ m3) EPS.

Glue: Certified Structural Adhesive from U.S.A.

Different facing Sips such as fiber cement board, gypsum board can also be the facing, Call for quotation.

No charge for standard edge routs specified with order. Standard routs are flush, 3/4", 1 1/2" or 3". OSB spline routs available for $2.00 per panel as specified.

Electrical chases available for $2.00 each per panel. Chases must be specified prior to lamination.

All panels can be precut to greatly save the onsite labor cost for USD 0.9/sf. (pls note the footage is based on the raw material will be used)

Definition:

Fiber Cement Board Sips are high performance thermal efficient composite panels which consist of a sandwich of two layers of structural board with an insulating layer of foam in between for walls, roofs and floors in new residential and commercial buildings.

Design theory:

Fiber Cement Board Sips have become a widely used alternative construction material for homes and other buildings. While many types of Composite Panel building systems have been developed, Sips now usually refers to panels made from a thick layer of foam (polystyrene or polyurethane) sandwiched between two layers of Oriented Strand Board (OSB), plywood or Fiber Cement Board Sips. The result is an engineered panel that provides structural framing, insulation, and exterior sheathing in a solid, one-piece component.

The basic design concept for SIPs is elegant in its simplicity, and offers several advantages for constructing walls and roofs. Bonding the foam core to the stiff outer skins creates a web-and-flange structural strength (along the same principal as an I-beam) across the length and breadth of the panel. With the capacity to handle axial, bending, racking, and shear loads, properly designed and assembled SIPs not only replace conventional framing, but will withstand high wind, and seismic forces.

Advantages to use Fiber Cement Board Sips:

Architectural Benefits

High quality construction method.

Comfortably warm, clean, and quiet.

Cost Benefits

Equal or lower first costs.

Lower long term operating costs.

Incentives available from utility service provider for energy efficient design.

Lower maintenance costs for you.

Construction Process Benefits

Easy to construct, with short learning curve.

60% shorter construction time

Quick turnaround time for greater satisfaction.

Increased builders production capacity.

Environmental Benefits

50% less framing lumber.

50% more energy efficient.

Requires less room at building site (less site disturbance).

Less construction waste.

Usage of Fiber Cement Board Sips:

SIPs are prefabricated systems used primarily for walls and roofs. SIPs employ composite materials, reduce waste through Modular construction methods, achieve high insulation

Fiber Cement Board Sips Thermal Performance System:

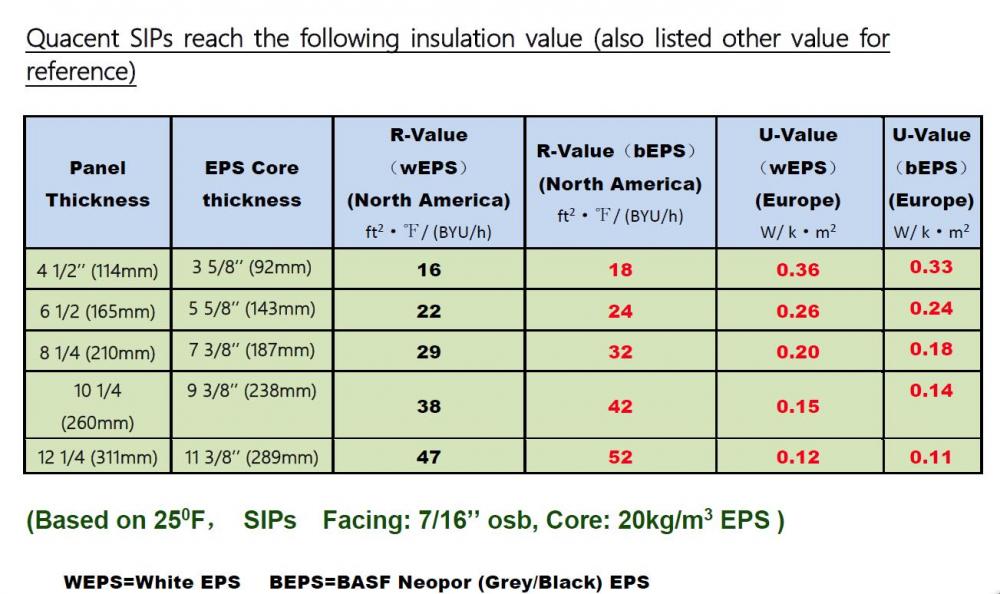

The Quacent SIP s System provides wall and roof assemblies with higher overall (effective) thermal resistance (R-value) than other conventional construction methods. The overall R-value of a building assembly includes the effect of thermal bridges as a result of framing members and is a measure of its ability to resist heat flow through it. The higher the overall R-value of a building assembly, the lower the long-term energy costs will be for heating and cooling.

The table below provides typical R-Values of SIPs in different thickness:

leakage rate for a building (quantified in terms of air changes per hour) is often used to determine the energy efficiency of building construction. Air leakage rates vary widely for different types of house construction with values of 0.2 acph or lower achievable for energy efficient house construction using the Quacent SIP System.

The combined high overall R-Value and low air leakage characteristic of buildings built with the Quacent Insulated Panels System results in significantly lower energy costs versus other constructi

Contact us if you need more details on Fiber Cement Skin Panels. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cementitious Structural Insulated Panels、Fiber Cement Sandwish Panels. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Structural Insulated Panels > Fiber Cement Board SIPs